GET A QUOTE

Get More Info

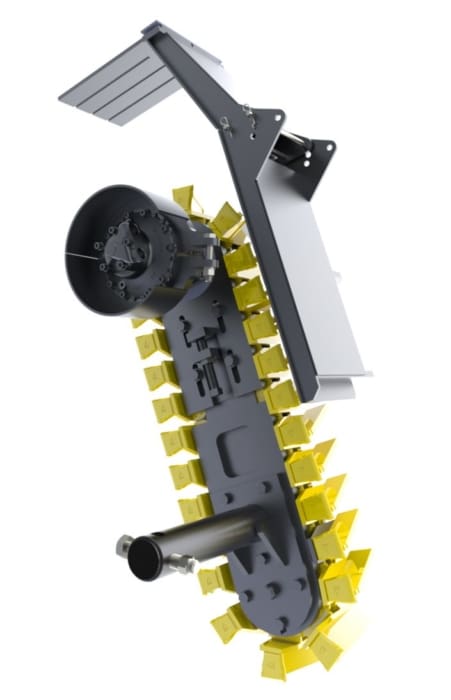

Dymax Rail Ballast Blaster Undercutters outperform all other methods for ballast removal. Some rail networks prefer it to conventional on-track ballast cleaners, as they are more efficient and easier to get on and off track, especially congested networks with severe time restraints. Our Ballast Blaster Undercutter will more than double productivity and cut operating costs by more than half! Get the work done within limited track time. The Ballast Blaster is the safest to operate and easiest to maintain undercutter on the market and it exceeds the productivity and durability of every brand of undercutter.

The Dymax Rail Ballast Blaster is the world’s first undercutter with full 360° continuous rotation. The added flexibility gives operators the ability to work from either side of the tracks. It also greatly improves management of spoil piles, allowing operators flexibility and maximum cutting speed and performance.

Dymax Rail Ballast Blasters are also available to fit tilt-rotator coupler systems.

Full rotation design for fitting pin grab couplers on excavator or backhoe loader. Full manipulation control allowing machines to cut from any position on either side of the railroad tracks. Easy service interface with the latest undercutting technology. Available in 4 cutting lengths.

For fitting tiltrotator quick coupler systems similar to Engcon, Rototilt, Steelwrist, SMP among others. Easy service interface available in 5 cutting lengths.

Powerful rotator system delivers up to 180 degrees of rotation using hydraulic cylinder power which makes the NXG-180 ideal for larger machinery. Easy service interface with the latest undercutting technology. Available in 2 cutting lengths.

The Spoilmaster™ can be added to the Dymax Rail 10 foot, 12 foot, and 15 foot Ballast Blasters. Spoilmaster™ requires an additional hydraulic circuit with case drain, which requires minimal oil flow and pressure. Spoilmaster™ does not require high cost adaptive hydraulic power units to be added to the machine, and works with standard excavator hydraulics that can easily be removed from the Ballast Blaster when not required.

Spoilmaster™ is smarter, more efficient, and delivers excellent performance. It’s spoil management simplified. Contact Dymax Rail for hydraulic information to see if Spoilmaster™ will work on your specific machine size.

Features

Options

Specifications

| Model ID | Model Code | Description | Features | Weight (LBS) |

| Backhoe Loader | ||||

| 102748 | DX-UC-BB-6ftx360-BL-10 | Undercutter – Ballast Blaster – 6 feet cutting length x 360 rotation – Backhoe Loader – Class 10 | Standard Features: NXG • 6ft cut length x 4.1″ cut • Patented Bar with replaceable carbide wear plates • Mechanical Chain Adjuster • Bi directional cut chain • Hi Torque motor • 360 rotator • Bar tilt actuator with 24v electro-valve • Armor guard | 1800 |

| 102749 | DX-UC-BB-8ftx360-BL-20 | Undercutter – Ballast Blaster – 8 feet cutting length x 360 rotation – Backhoe Loader – Class 20 | Standard Features: NXG • 8ft cut length x 4.1″ cut • Patented Bar with replaceable carbide wear plates • Mechanical Chain Adjuster • Bi directional cut chain • Hi Torque motor • 360 rotator • Bar tilt actuator with 24v electro-valve • Armor guard | 2100 |

| Hydrauilc Excavator | ||||

| 102747 | DX-UC-BB-8ftx360-HX-8T | Undercutter – Ballast Blaster – 8 feet cutting length x 360 rotation – Hydraulic Excavator – 8 Ton | Standard Features: NXG • 8ft cut length x 4.1″ cut • Patented Bar with replaceable carbide wear plates • Mechanical Chain Adjuster • Bi directional cut chain • Hi Torque motor • 360 rotator • Bar tilt actuator with 24v electro-valve • Armor guard | 2100 |

| 102754 | DX-UC-BB-8ftxTRQ-HX-8T | Undercutter – Ballast Blaster – 8 feet cutting length x Tilt Rotator Coupler connection – Hydraulic Excavator – 8 Ton | Standard Features: NXG • 8ft cut length x 4.1″ cut • Patented Bar with replaceable carbide wear plates • Mechanical Chain Adjuster • Bi directional cut chain • Hi Torque motor • Tiltrotator Hookup • Armor guard | 1500 |

| 102750 | DX-UC-BB-9ftx180-HX-12T | Undercutter – Ballast Blaster – 9 feet cutting length x 180 rotation cylinder – Hydraulic Excavator – 12 Ton | Standard Features: NXG • 9ft cut length x 6.1″ cut • Patented Bar with replaceable carbide wear plates • Patented Auto Chain Adjuster • Bi directional HD cut chain • Hi Torque motor • 180 rotator • Bar tilt actuator with 24v electro-valve • Armor guard | 4100 |

| 102889 | DX-UC-BB-9ftx360-HX-12T | Undercutter – Ballast Blaster – 9 feet cutting length x 360 rotation – Hydraulic Excavator – 12 Ton | Standard Features: NXG • 9ft cut length x 6.1″ cut • Patented Bar with replaceable carbide wear plates • Patented Auto Chain Adjuster • Bi directional HD cut chain • Hi Torque motor • 360 rotator • Bar tilt actuator with 24v electro-valve • Armor guard | 4500 |

| 102751 | DX-UC-BB-10ftx180-HX-14T | Undercutter – Ballast Blaster – 10 feet cutting length x 180 rotation cylinder – Hydraulic Excavator – 14 Ton | Standard Features: NXG • 10ft cut length x 6.1″ cut • Patented Bar with replaceable carbide wear plates • Patented Auto Chain Adjuster • Bi directional HD cut chain • Hi Torque motor • 180 rotator • Bar tilt actuator with 24v electro-valve • Armor guard | 4800 |

| 102891 | DX-UC-BB-10ftx360-HX-14T | Undercutter – Ballast Blaster – 10 feet cutting length x 360 rotation – Hydraulic Excavator – 14 Ton | Standard Features: NXG • 10ft cut length x 6.1″ cut • Patented Bar with replaceable carbide wear plates • Patented Auto Chain Adjuster • Bi directional HD cut chain • Hi Torque motor • 360 rotator • Bar tilt actuator with 24v electro-valve • Armor guard | 5000 |

| 102755 | DX-UC-BB-10ftxTRQ-HX-14T | Undercutter – Ballast Blaster – 10 feet cutting length x Tilt Rotator Coupler connection – Hydraulic Excavator – 14 Ton | Standard Features: NXG • 10ft cut length x 6.1″ cut • Patented Bar with replaceable carbide wear plates • Patented Auto Chain Adjuster • Bi directional HD cut chain • Hi Torque motor • Tiltrotator hookup | 2950 |

| 102752 | DX-UC-BB-12ftx180-HX-20T | Undercutter – Ballast Blaster – 12 feet cutting length x 180 rotation cylinder – Hydraulic Excavator – 20 Ton | Standard Features: NXG • 12ft cut length x 6.1″ cut • Patented Bar with replaceable carbide wear plates • Patented Auto Chain Adjuster • Bi directional HD cut chain • Hi Torque motor • 180 rotator • Bar tilt actuator with 24v electro-valve • Armor guard | 5600 |

| 102758 | DX-UC-BB-12ftxTRQ-HX-18T | Undercutter – Ballast Blaster – 12 feet cutting length x Tilt Rotator Coupler connection – Hydraulic Excavator – 18 Ton | Standard Features: NXG • 12ft cut length x 6.1″ cut • Patented Bar with replaceable carbide wear plates • Patented Auto Chain Adjuster • Bi directional HD cut chain • Hi Torque motor • Tiltrotator hookup | 3650 |

| 102753 | DX-UC-BB-15ftx180-HX-25T | Undercutter – Ballast Blaster – 15 feet cutting length x 180 rotation cylinder – Hydraulic Excavator – 25 Ton | Standard Features: NXG • 15ft cut length x 6.1″ cut • Patented Bar with replaceable carbide wear plates • Patented Auto Chain Adjuster • Bi directional HD cut chain • Hi Torque motor • 180 rotator • Bar tilt actuator with 24v electro-valve • Armor guard | 6400 |

| 102757 | DX-UC-BB-15ftxTRQ-HX-25T | Undercutter – Ballast Blaster – 15 feet cutting length x Tilt Rotator Coupler connection – Hydraulic Excavator – 25 Ton | Standard Features: NXG • 15ft cut length x 6.1″ cut • Patented Bar with replaceable carbide wear plates • Patented Auto Chain Adjuster • Bi directional HD cut chain • Hi Torque motor • Tiltrotator hookup | 4400 |

| 100093 | DX-UC-BB-SMS-HX-25T | Undercutter – Ballast Blaster – Spoil Management System – Hydraulic Excavator – 25 Ton | Standard Features: HD motor group, 2 position angles and paddle chain with mechanical adjuster | 1130 |

Design and specifications are subject to change without notice

Hydraulic Requirements

| Model ID | Model Code | Hydraulic Requirements |

| Backhoe Loader | CIR1 (circuit 1) CIR2 (circuit 2) CIR3 (circuit 3) | |

| 102748 | DX-UC-BB-6ftx360-BL-10 | CIR1-Chain Motor, Type Two way + drain line to tank, GPM/PSI (min/max): 24-30 / 4,500 CIR2-Rotator, Type – Two way GPM/PSI (max): 10 / 3,000 CIR3-Bar Tilt, Type Electro-Hydraulic Valve Kit – requires install Not provided with Jumper Lines to machine. |

| 102749 | DX-UC-BB-8ftx360-BL-20 | CIR1-Chain Motor, Type Two way + drain line to tank, GPM/PSI (min/max): 24-30 / 4,500 CIR2-Rotator, Type – Two way GPM/PSI (max): 10 / 3,000 CIR3-Bar Tilt, Type Electro-Hydraulic Valve Kit – requires install Not provided with Jumper Lines to machine. |

| Hydraulic Excavator | ||

| 102747 | DX-UC-BB-8ftx360-HX-8T | CIR1-Chain Motor, Type Two way + drain line to tank, GPM/PSI (min/max): 24-30 / 4,500 CIR2-Rotator, Type – Two way GPM/PSI (max): 10 / 3,000 CIR3-Bar Tilt, Type Electro-Hydraulic Valve Kit – requires install Not provided with Jumper Lines to machine. |

| 102754 | DX-UC-BB-8ftxTRQ-HX-8T | CIR1-Chain Motor, Type Two way + drain line to tank, GPM/PSI (min/max): 24-30 / 4,500 Not provided with Jumper Lines to machine. |

| 102750 | DX-UC-BB-9ftx180-HX-12T | CIR1-Chain Motor, Type Two way + drain line to tank, GPM/PSI (min/max): 30-34 / 4,500 CIR2-Rotator, Type – Two way GPM/PSI (max): 10 / 3,000 CIR3-Bar Tilt, Type Electro-Hydraulic Valve Kit – requires install Not provided with Jumper Lines to machine. |

| 102889 | DX-UC-BB-9ftx360-HX-12T | CIR1-Chain Motor, Type Two way + drain line to tank, GPM/PSI (min/max): 30-34 / 4,500 CIR2-Rotator, Type – Two way GPM/PSI (max): 10 / 3,000 CIR3-Bar Tilt, Type Electro-Hydraulic Valve Kit – requires install Not provided with Jumper Lines to machine. |

| 102751 | DX-UC-BB-10ftx180-HX-14T | CIR1-Chain Motor, Type Two way + drain line to tank, GPM/PSI (min/max): 36-42 / 4,500 CIR2-Rotator, Type – Two way GPM/PSI (max): 10 / 3,000 CIR3-Bar Tilt, Type Electro-Hydraulic Valve Kit – requires install Not provided with Jumper Lines to machine. |

| 102891 | DX-UC-BB-10ftx360-HX-14T | CIR1-Chain Motor, Type Two way + drain line to tank, GPM/PSI (min/max): 36-42 / 4,500 CIR2-Rotator, Type – Two way GPM/PSI (max): 10 / 3,000 CIR3-Bar Tilt, Type Electro-Hydraulic Valve Kit – requires install Not provided with Jumper Lines to machine. |

| 102755 | DX-UC-BB-10ftxTRQ-HX-14T | CIR1-Chain Motor, Type Two way + drain line to tank, GPM/PSI (min/max): 36-42 / 4,500 Not provided with Jumper Lines to machine. |

| 102752 | DX-UC-BB-12ftx180-HX-20T | CIR1-Chain Motor, Type Two way + drain line to tank, GPM/PSI (min/max): 38-42 / 4,500 CIR2-Rotator, Type – Two way GPM/PSI (max): 10 / 3,000 CIR3-Bar Tilt, Type Electro-Hydraulic Valve Kit – requires install Not provided with Jumper Lines to machine. |

| 102758 | DX-UC-BB-12ftxTRQ-HX-18T | CIR1-Chain Motor, Type Two way + drain line to tank, GPM/PSI (min/max): 38-42 / 4,500 Not provided with Jumper Lines to machine. |

| 102753 | DX-UC-BB-15ftx180-HX-25T | CIR1-Chain Motor, Type Two way + drain line to tank, GPM/PSI (min/max): 45-50 / 4,500 CIR2-Rotator, Type – Two way GPM/PSI (max): 10 / 3,000 CIR3-Bar Tilt, Type Electro-Hydraulic Valve Kit – requires install Not provided with Jumper Lines to machine. |

| 102757 | DX-UC-BB-15ftxTRQ-HX-25T | CIR1-Chain Motor, Type Two way + drain line to tank, GPM/PSI (min/max): 45-50 / 4,500 Not provided with Jumper Lines to machine. |

| 100093 | DX-UC-BB-SMS-HX-25T | CIR1 – Motor, Type one-way plus drain line to tank, GPM (min/max): 10-15, PSI (max): 3,000, Not provided with Jumper Lines to machine, Route drain on it’s own line never connect to existing drain line on high efficiency motor. |

Design and specifications are subject to change without notice

402 Miller Drive

PO Box 297

Wamego, KS 66547

United States

Toll Free: 1-800-530-5407

Phone: 1-785-456-2081

Fax: 785-456-8328

Email: [email protected], [email protected]

Monday – Friday:

8:00 am – 5:00 pm

www.dymaxrail.com

www.dymaxinc.com

Dymax, Inc. © 2022. All Rights Reserved.

Railcar Coupler

Railcar CouplerThis site uses cookies. By continuing to browse the site, you are agreeing to our use of cookies.

OKLearn moreWe may request cookies to be set on your device. We use cookies to let us know when you visit our websites, how you interact with us, to enrich your user experience, and to customize your relationship with our website.

Click on the different category headings to find out more. You can also change some of your preferences. Note that blocking some types of cookies may impact your experience on our websites and the services we are able to offer.

These cookies are strictly necessary to provide you with services available through our website and to use some of its features.

Because these cookies are strictly necessary to deliver the website, refusing them will have impact how our site functions. You always can block or delete cookies by changing your browser settings and force blocking all cookies on this website. But this will always prompt you to accept/refuse cookies when revisiting our site.

We fully respect if you want to refuse cookies but to avoid asking you again and again kindly allow us to store a cookie for that. You are free to opt out any time or opt in for other cookies to get a better experience. If you refuse cookies we will remove all set cookies in our domain.

We provide you with a list of stored cookies on your computer in our domain so you can check what we stored. Due to security reasons we are not able to show or modify cookies from other domains. You can check these in your browser security settings.

These cookies collect information that is used either in aggregate form to help us understand how our website is being used or how effective our marketing campaigns are, or to help us customize our website and application for you in order to enhance your experience.

If you do not want that we track your visit to our site you can disable tracking in your browser here:

We also use different external services like Google Webfonts, Google Maps, and external Video providers. Since these providers may collect personal data like your IP address we allow you to block them here. Please be aware that this might heavily reduce the functionality and appearance of our site. Changes will take effect once you reload the page.

Google Webfont Settings:

Google Map Settings:

Google reCaptcha Settings:

Vimeo and Youtube video embeds:

The following cookies are also needed - You can choose if you want to allow them:

You can read about our cookies and privacy settings in detail on our Privacy Policy Page.

Privacy Policy