Rocket Launch Supported by Dymax’s Innovative Rail Cart Chassis

When Amazon launched Project Kuiper, they probably didn’t know they were blasting off from a series of Dymax-built specialized rail carts.

DymaxRail and Redguard, two excellent Kansas companies, delivered a key solution to help move United Launch Alliance’s Atlas and Vulcan rockets to and from the launch pad. 🚀Check it out! https://youtu.be/4CScMjPE744

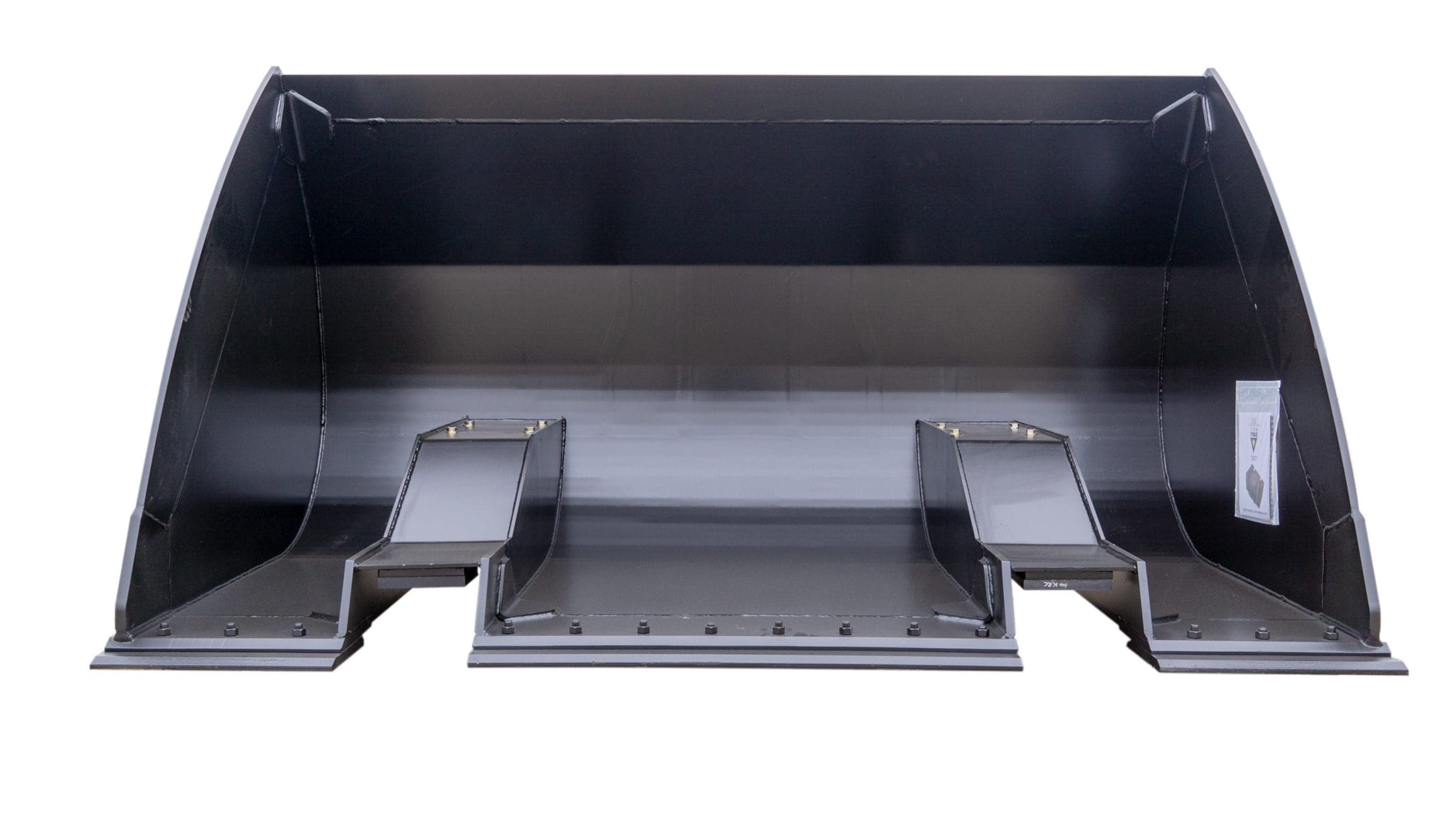

These specialized carts were made in various sizes to match a steel blast room fabricated by our partners at Red Guard. We built them strong enough to withstand hurricane-force winds and extreme heat.

While many customers know Dymax for our railway track maintenance and construction type jobs, we also build many carts for special applications.

“We’re able to build heavier capacities than most and offer flexibility in custom design to better meet our customers’ needs. In such cases as ULA’s applications at Cape Canaveral, we are able to reduce the height and provide 60 ton capacities,” said Scott Balderson, Dymax CEO. “That’s kind of our sweet spot, from 30 to 100 tons. There’s very few companies that can do that.”

As a leader in the rail rolling logistics industry, Dymax is pushing the boundaries of what’s possible beyond our atmosphere – and right here at home.